Resource-saving and risk-free

High-speed production for the medical industry

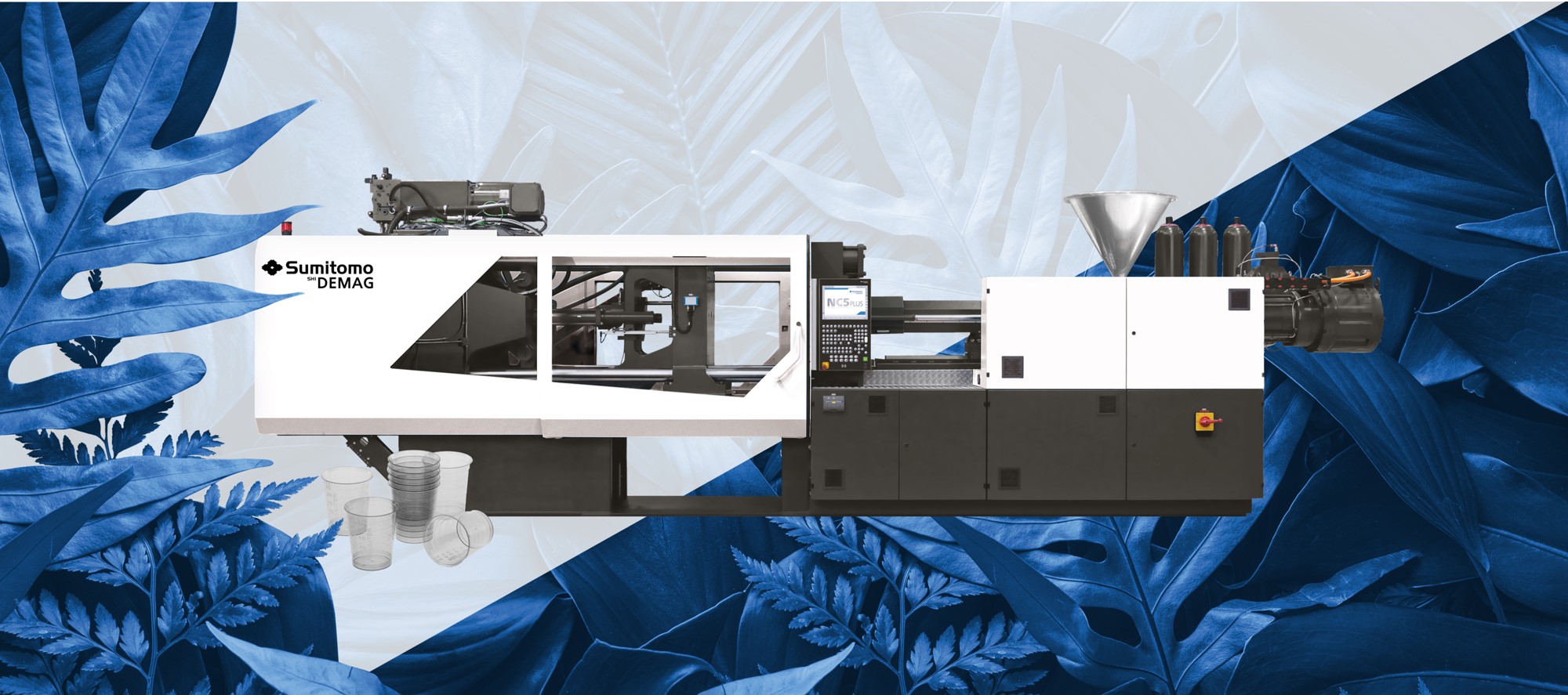

We will demonstrate our expertise in the medical sector with an El-Exis SP 420 hybrid high-speed machine. In the joint project “Med Cup” together with Zubler Handling AG and Otto-Hofstetter AG, medicine cups made of PP with a capacity of 30 millilitres are manufactured.

The concept of the joint project is to combine maximum energy efficiency with the optimised use of material while ensuring the highest quality. The use of less material allows the mould to cool down more quickly, which means that the injected material solidifies faster and the production cycle can be repeated more quickly and more frequently. The result is an ultra-short moulding process combined with high-speed extraction, enabling the machine to release and analyse 48 cups in less than three seconds.

K 2022 Med-Cup-Application

- High repeatability

- NC5-control with parameter setting for risk minimization

- High-speed production with a maximum of energy efficiency

- Barrier Screw 70mm L/D 25 with Dipping Nozzle

- Cooling water distribution below mould area (side entry robot)

- Lubrication according FDA Standards (H1)

- Integrated Interfaces (Euromap 67 and 78 for automation, Euromap 77 for host-computer)

- Side entry robot with take out time below 0,6sec

- Camera control (12 cameras, 96 images per 3sec cycle)

- Samle output unit

- 48 cavity hotrunner tool

- Specifically designed for thinwall applications

- Length: 42mm

- Wall thickness: 0,3mm

- Part weight: 1,4g

- Borealis RJ 880MO

Our El-Exis SP can produce resource-saving medication cups exceptionally energy-efficiently on a small footprint.

Anatol Sattel, Director Business Development Medical