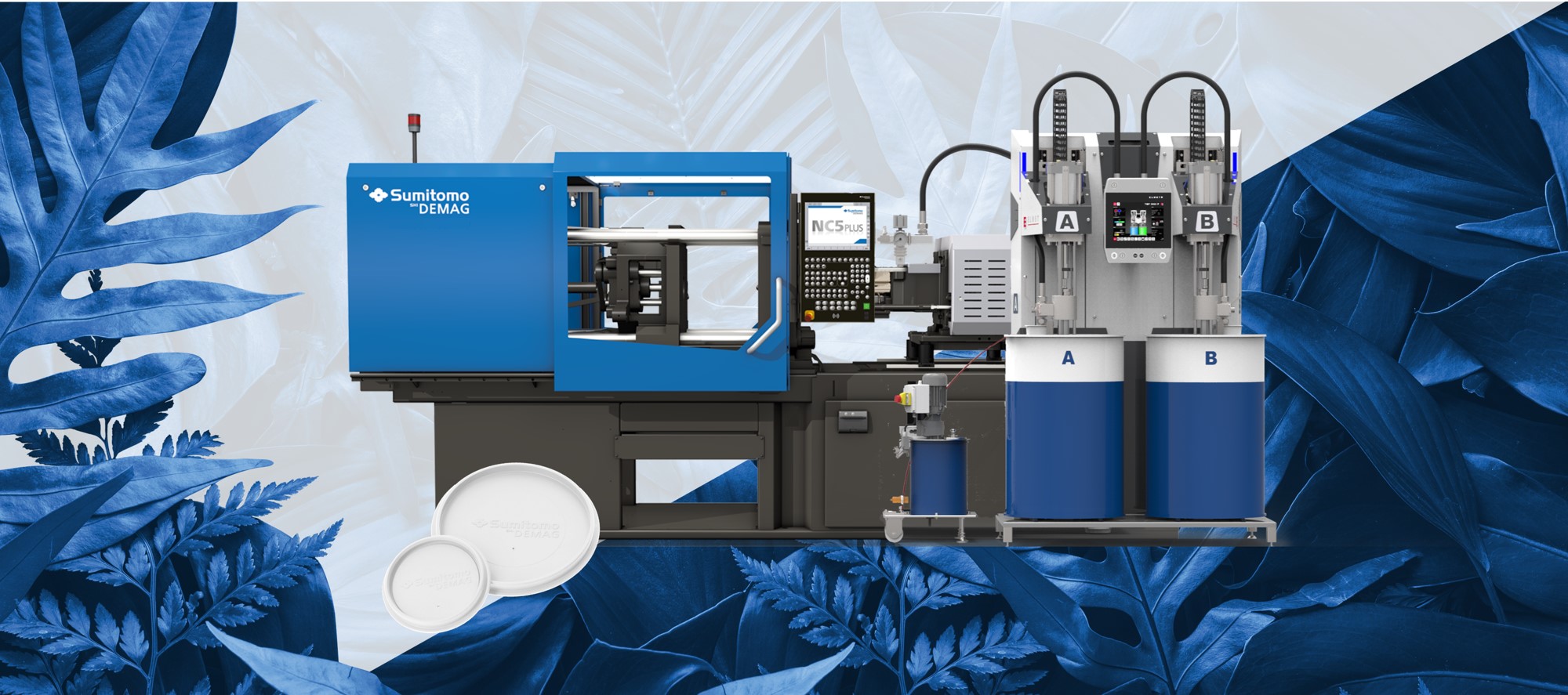

Fully integrated LSR solution with robot novelty

We demonstrate our LSR process expertise and the compatibility of the OPC-UA interface for common metering systems on an IntElect 180 all-electric injection molding machine. It is used to produce four different, durable and reusable covers for drinking and food cans - so-called smart caps - in a single mold. This makes a contribution to sustainability, true to our trade show slogan 'Act! Sustainably'.

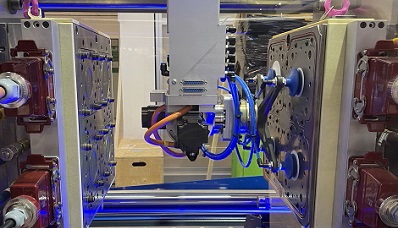

The production cell also includes our robot novelty SAM-S. It is a 6-axis hybrid robot comprising Scara mechanics and linear robotics. With two payload sizes (12kg and 25kg) currently planned, the SAM-S series is suitable for applications where a linear robot is considered too inflexible, yet industrial robots too complex for operators.

K 2022 LSR application

- LSR package

- Energy efficient

- Highly precise

- Dynamic

- Clean production cell

- 12kg payload

- 6 axis kinematic design

- Sumitomo drive technology

- Integrated control interface

- Lasermarking unit for silicone parts

- Part weight unit for sorting of different sized parts

- Including dosing system

- Specifically designed for LSR applications and for burr-reduction

- 4 different-sized cavities

- Including EOAT

- Reusable

- Part weight: 42g

- 4 sizes from one tool

- Laser marking

- LSR White

In this exhibit, SAM-S shows its three most important features - a large work envelope, its integrated operation, and its special design featuring Sumitomo drive technology.

Jürgen Schulze, Director Automation